Engineering Articles

DC HI-POT TEST

Abstract - Overvoltage tests, also known as high potential or "Hi-Pot", are used frequently to ensure the minimum dielectric strength of the insulation system. It is not a destructive test, nor does it degrade materials. These tests are carried out in whole or in part of the winding, to test the ground condition of the insulation of rotating electric machines.

DC HI-POT TEST

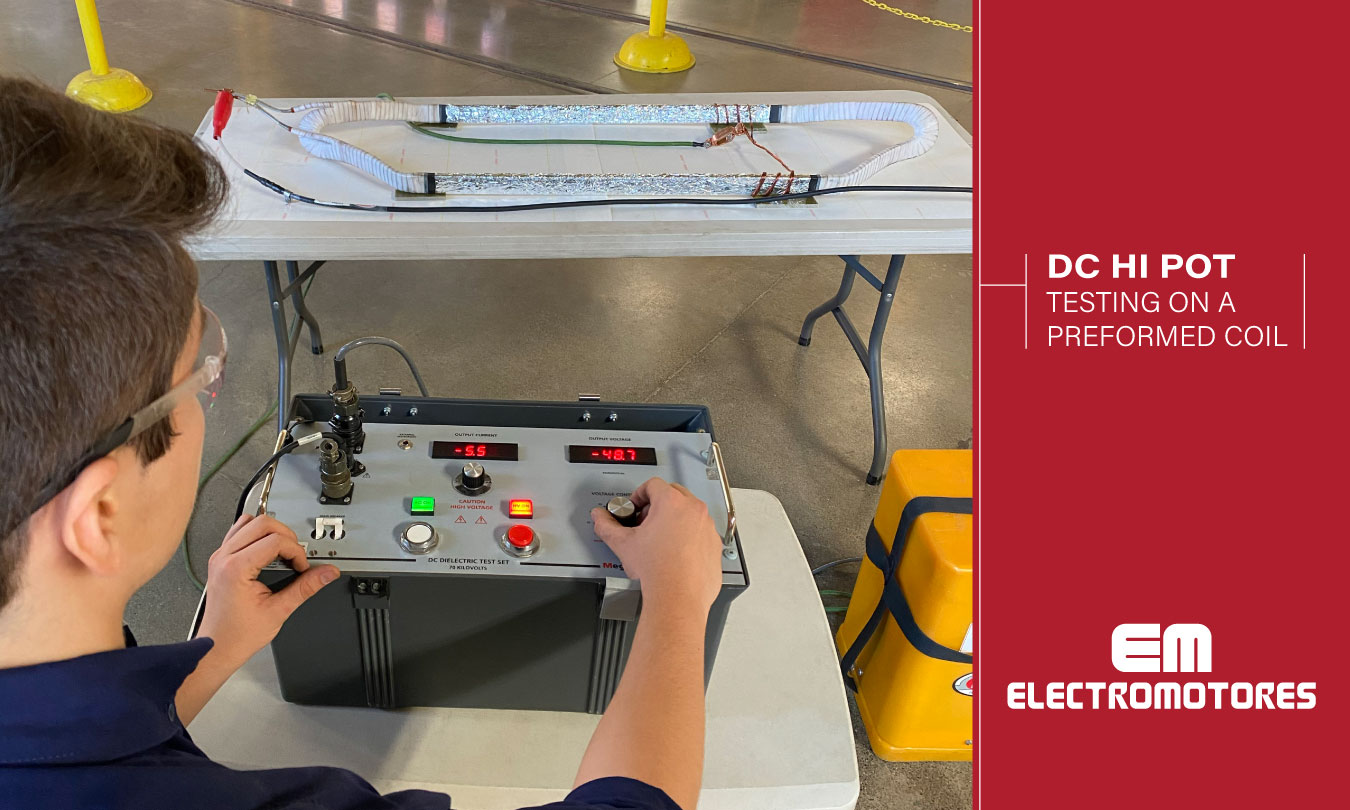

It is common for users of motors and generators to apply DC tests (Hi-Pot in DC) periodically [1]. This enables on-site detection of weaknesses in the insulation system, and their repair during a scheduled outage. It is also a routine test to verify the condition of the ground insulation when machines are built or repaired [2]. They should be applied, whenever possible, by phase, with the remaining two phases and the auxiliary devices grounded.

Hi-Pot DC tests are helpful in discerning any advanced or emerging weaknesses in the insulation structure that may lead to failures during service. The test is a useful tool to detect various problems, such as: cracks and fissures, moisture absorption, separations of insulating tapes, contamination, inadequate cure, and internal delamination in the epoxy / mica layers of the winding.

A recurring question is whether the test is destructive. The answer to this question is NO, often asked by maintenance managers, who have to approve the application of Hi-Pot testing to their machines. Furthermore, such tests DO NOT introduce any significant degradation into a machine with a good insulation system. Machines that failed during a Hi-Pot test have always had a poor insulation system, confirmed in a post-failure examination [3]. In contrast, good insulation will normally withstand 2-3 times the voltage applied in Hi-Pot DC.

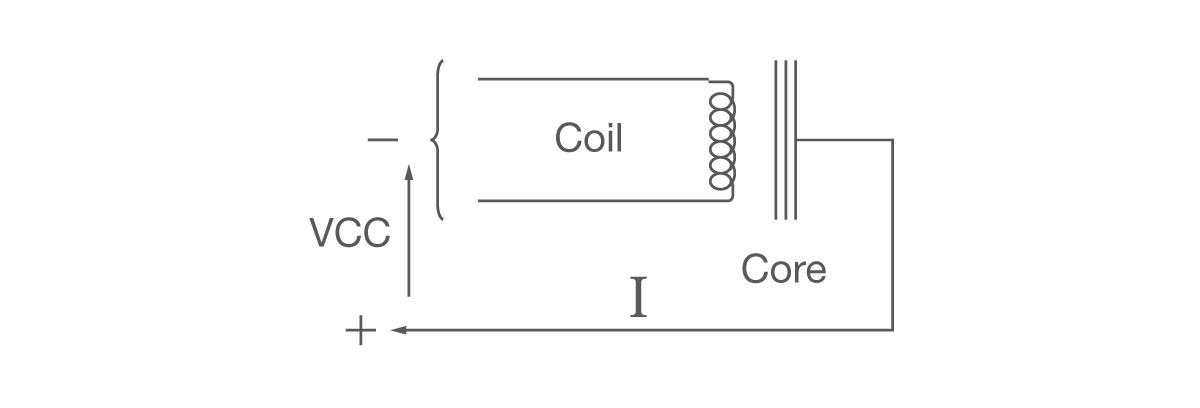

When a DC voltage is applied to a stator of a rotating electric machines, as shown in Fig. 1, between the winding and the frame (ground), the ground insulation is tested. A current “I” appears, which is produced by 2 factors, which are:

- Surface leakage current: A current that is constant with time, and which usually exists over the surface of the end-turns of the stator winding or between exposed conductors and the rotor body in insulated rotor windings. The magnitude of the surface leakage current is dependent upon temperature and the amount of conductive material, e.g., moisture or contamination on the surface of the insulation. [4]

- Absorption current: A current resulting from molecular polarizing and electron drift, which decays with time of voltage application at a decreasing rate from a comparatively high initial value to nearly zero, and depends on the type and condition of the insulation system. [4]

Figure 1: Basic setup of a DC Hi-Pot test.

For DC Hi-Pot testing, the recommended voltage is a function of the nominal machine voltage multiplied by a factor to represent the relationship between the test voltage (DC) and the alternating voltage (RMS). The selection of the maximum voltage is as follows [2]:

- Acceptance test: for new and rewound machines, whether in the factory, in the workshop or on site. The test voltage is 1.7 times [2E + 1000] V (where: E is the line-line voltage).

- Maintenance test: for machines in service “operation”. The test is performed at the voltage between 65% and 75% of the value 1.7 times [2E + 1000] V.

The voltage applied to the winding must be gradual, to avoid exceeding the maximum test voltage. Its duration is typically one minute (most cases), and can be as long as ten minutes (some cases), counted from when the maximum voltage value is reached. When the test is complete, the voltage source is reduced to zero and the winding must be grounded.

Experts recommend to do the Hi-Pot DC for machines in service every 3-5 years, ideally coinciding with major maintenance work and as a way to recertify the condition of the unit. Upon passing the test, the insulation system is considered to be robust enough for reliable operation.

REFERENCES

- B. Gupta, G. Stone, and J. Stein Stator Winding Hipot (high potential) Testing,” in Electrical Insulation Conference EIC, 2009, no. June, pp. 409–413, doi: 10.1109/EIC.2009.5166381.

- IEEE Std 95 Recommended Practice for Insulation Testing of AC Electric Machinery (2300 V and Above) With High Direct Voltage. USA, 1995, pp. 1–57.

- G. Stone, “Stator Winding Hipot Testing,” Iris Power, no. February, Toronto, pp. 1–4, 2007.

- IEEE Std 43 Recommended Practice for Testing Insulation Resistance of Rotating Machinery.. USA, 2013, pp. 1–26.